In this video, I explore a critical yet often overlooked topic: why some people neglect emergency preparedness and even react negatively when it’s suggested. Despite the regular occurrences of severe weather and power outages, many remain unprepared for these disruptions. This discussion goes deeper, examining the potential aftermath of a major event like an EMP, CME, cyber-attack, terrorist attack, or war that could lead to a long-term grid failure.

I’ll dissect the psychology behind this lack of preparedness, the consequences of being caught unprepared, and emphasize the importance of readiness for even the most severe scenarios. The video also provides practical advice on preparing for these extreme situations, ensuring you have essential survival skills and knowledge for any unforeseen event.

Whether you’re just starting to think about emergency preparedness or are seeking to deepen your understanding, this video offers insights and tips for everyone. Subscribe for more discussions on survival strategies, preparedness, and adapting to life without everyday conveniences. Stay informed, stay prepared!

Click here to watch the video on YouTube.

by Dan W

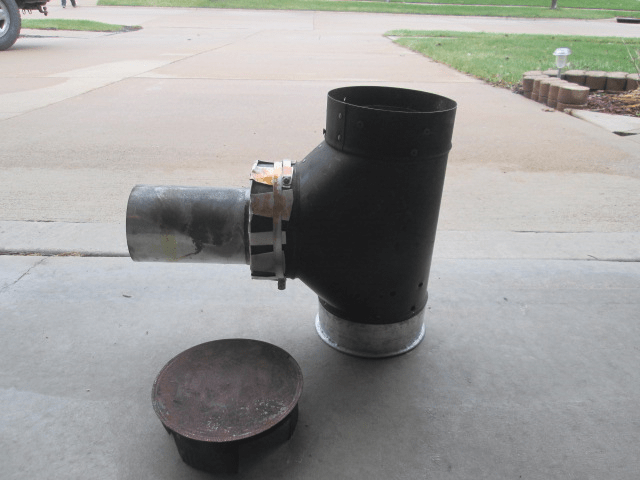

by Dan W The search was on for a wood-fired cookstove that could be moved into place within the home and be safely put to use if/when the SHTF. I did not want to cut a hole in the roof for chimney pipe to pass through …….. a chimney thimble (just in case) mounted in our T&G roof decking was not acceptable to us. It would also mean that we’d have to get on our steep metal roof to initially install the chimney pipe and remove it when it needed cleaning.

The search was on for a wood-fired cookstove that could be moved into place within the home and be safely put to use if/when the SHTF. I did not want to cut a hole in the roof for chimney pipe to pass through …….. a chimney thimble (just in case) mounted in our T&G roof decking was not acceptable to us. It would also mean that we’d have to get on our steep metal roof to initially install the chimney pipe and remove it when it needed cleaning. by Jeff in Ohio

by Jeff in Ohio  by Jacki

by Jacki

By Michael C

By Michael C

by Repair Mama

by Repair Mama

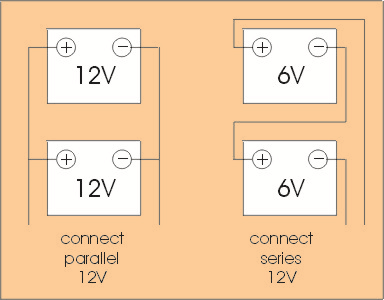

Searching online shows the full range of battery types. The true deep cycle batteries have AH ratings that are high but so is the price tag. Many of the lead-acid and AGM batteries are 6V which means you would need to buy them in pairs. One pair would be hooked up in series to make 12V. That means positive post of one 6V battery to the negative post of the other, and negative post of the first battery to the positive post of the other.

Searching online shows the full range of battery types. The true deep cycle batteries have AH ratings that are high but so is the price tag. Many of the lead-acid and AGM batteries are 6V which means you would need to buy them in pairs. One pair would be hooked up in series to make 12V. That means positive post of one 6V battery to the negative post of the other, and negative post of the first battery to the positive post of the other. Most of the time we will need 120V power for the existing appliances. There will be a need for an inverter. It will take the 12V power and produce the 120V that need. Since we have estimated or measured the amount of the appliances will use we can use this to decide how large of an inverter is needed.

Most of the time we will need 120V power for the existing appliances. There will be a need for an inverter. It will take the 12V power and produce the 120V that need. Since we have estimated or measured the amount of the appliances will use we can use this to decide how large of an inverter is needed. The first mobile inverter I had was a 1000W major brand that came from the solar expert’s store. It proved to be completely inadequate. What I later learned was that the total wattage is split among the outlets. So if the inverter produces a total of 1000 watts and has 2 outlets, each outlet can support a load of 500W.

The first mobile inverter I had was a 1000W major brand that came from the solar expert’s store. It proved to be completely inadequate. What I later learned was that the total wattage is split among the outlets. So if the inverter produces a total of 1000 watts and has 2 outlets, each outlet can support a load of 500W. By Sandra

By Sandra by Dan W

by Dan W

Setting up and using a shortwave system is more complex than using CB devices. There is a definite need for both types of devices in a complete communications system, but did we want to purchase and set up both types? Would only one type suit our needs?

Setting up and using a shortwave system is more complex than using CB devices. There is a definite need for both types of devices in a complete communications system, but did we want to purchase and set up both types? Would only one type suit our needs?